+

+  =

=

Shatnez Lab of Houston

revised 1/9/12 (second site soon)The Shatnez Lab of Houston has been organized, with the assistance of Rabbi Wender of the Young Israel of Houston, to serve the community with accurate, speedy, and economical shatnez checking and testing. Both checkers have been trained by Rabbi Yosef Sayagh of the Lakewood Shatnez Laboratory,

and are part of his world-wide network of checkers. Frequent

alerts are disseminated regarding unusual and unexpected discoveries of shatnez, to which the Houston lab has contributed.

CHECKING ARRANGEMENTS

As

a convenience, we have established a secure and weatherproof SHATNEZ

CHECKING AUTO-DEPOSITORY in the Young Israel neighborhood. Drop

off in

the morning, and pick up the next day or by special arrangement the same

afternoon. Just put a twist-tie around your hangers, impale a

piece of paper on the hangers indicating your name, cell #, email, # of pieces in your order,

and hang up in the box. We'll check the box several times a day,

or let us know by email that

you've dropped something off. Call one of the checkers to find out

where the box is located. The AUTO-DEPOSITORY eliminates those halting

conversations of assignation, fixing times of meeting amenable to both

parties. Lately, we've added a set of steps for the vertically challenged. Now, it's no muss - no fuss for all your shatnez checking needs.

Prices are very reasonable: men's or women's jacket = $5.00, pants/skirt = $3.00, sweater = $5.00, children's garments = $3.00, other garments and bulk in-home inspection by request. If shatnez is found, the customer will be asked if the checker should remove it...for which there will be extra charges depending on the delicacy and difficulty of the task.

When you pick up your order, there'll be a receipt attached in an inoffensive manner to one of your garments. The whole story will be told...who and what was checked, what if anything was found, and how much you owe. Checks should be made payable to Rabbi Kessler, who is using the $$ currently for special classroom supplies at the Sephardic Gan.

Quite a few items that should be checked according to the guidelines below only need a cursory examination for which there will be no charge at all. This is a public service, not a money-making venture, and all the proceeds go to tzedakah.

For those with closets full of uninspected items we will set up a bulk service lab on your kitchen table, quickly separate those items that don't need checking, and expeditiously check those that do right on the spot. Service is charged on an hourly, not per-garment, basis so you save big bucks.

SHATNEZ GUIDELINES

3. All lined garments such as jackets or coats, regardless of fiber label, should be checked for shatnez.

4. All “linen-look” garments (having a varied or rusticated weave and lustre) should be checked for shatnez.

Other Fibers means that reprocessed fibers are used. There can be both wool and linen fibers present, hence a shatnez problem. If such a garment has been purchased it should be checked to see if it is permissible to wear.

Purchasing a garment from a frum or heimesh retailer, or which carries the label of a frum manufacturer does not mean that it is shatnez free.

Labels or retailers often contract with independent foreign subcontractors to produce garments. Unfortunately they either give loose specifications regarding internal materials, or the subcontractor makes unauthorized, undetected substitutions, resulting in the presence of shatnez. There have been many instances where reliance on the shatnez-free guarantees from frum retailers or manufacturers regarding their merchandise has been sadly mistaken.

Do not rely on any rule of thumb which states that the majority of garments made in country X are known to be free of shatnez, or conversely that the majority of garments made in country Y are known to contain shatnez.

Clothing manufacture is constantly changing. Manufacturers are always looking for cheaper suppliers and therefore the internal components of garments themselves constantly change. With the exception of traditional bespoke tailored garments and some military clothing made in Eastern Europe, there is almost no national culture of clothing manufacture remaining in the world.

You may not try on a garment that is known to contain shatnez.

If a garment is not known to contain shatnez, (meaning it might or might not) it may be tried on for size, but not worn until checked. A garment made by a manufacturer known to always contain shatnez (such as Hugo Boss or Aquascutum) according to most poskim, may not even be tried on.

Joseph A. Bank suits may contain shatnez.

Joseph A. Bank suit are very popular because they provide good value - are well made and often on sale at good prices. Many of their suits, particularly the Signature Gold series, often contain shatnez in the collar. All Joseph A. Bank suits, as with all men’s suits should be checked for shatnez. All are considered safeik shatnez and may be tried on.

All vintage garments made before 1939 and any bespoke tailored garments should be checked for shatnez.

Before WWII there were no synthetic fibers in practical use in the garment industry. Linen was used extensively as interfacing in all kinds of garments. Bespoke London tailors continue to use linen today in wool suits as a matter of tradition. This clothing is beautifully made and looks like a better value than its modern counterparts, but beware...the cost to remove the shatnez and remake the garment may be prohibitive.

Suits may be returned if found to contain shatnez after checking but before any alterations are made.

Prices are very reasonable: men's or women's jacket = $5.00, pants/skirt = $3.00, sweater = $5.00, children's garments = $3.00, other garments and bulk in-home inspection by request. If shatnez is found, the customer will be asked if the checker should remove it...for which there will be extra charges depending on the delicacy and difficulty of the task.

When you pick up your order, there'll be a receipt attached in an inoffensive manner to one of your garments. The whole story will be told...who and what was checked, what if anything was found, and how much you owe. Checks should be made payable to Rabbi Kessler, who is using the $$ currently for special classroom supplies at the Sephardic Gan.

Quite a few items that should be checked according to the guidelines below only need a cursory examination for which there will be no charge at all. This is a public service, not a money-making venture, and all the proceeds go to tzedakah.

For those with closets full of uninspected items we will set up a bulk service lab on your kitchen table, quickly separate those items that don't need checking, and expeditiously check those that do right on the spot. Service is charged on an hourly, not per-garment, basis so you save big bucks.

SHATNEZ GALLERY

JHV article on Shatnez Lab of Houston

MyKosherHome shatnez article

Ellen Tracy Woman's Jacket

Garments - Redeemed and Irredeemable

JHV article on Shatnez Lab of Houston

MyKosherHome shatnez article

Ellen Tracy Woman's Jacket

Garments - Redeemed and Irredeemable

SHATNEZ GUIDELINES

1. All wool garments should be checked for shatnez.

2. All linen garments should be checked for shatnez.3. All lined garments such as jackets or coats, regardless of fiber label, should be checked for shatnez.

4. All “linen-look” garments (having a varied or rusticated weave and lustre) should be checked for shatnez.

ADDITIONAL SHATNEZ TIPS

Be wary of garments that list “Other Fibers” (O.F.) on the fiber contents label.

Other Fibers means that reprocessed fibers are used. There can be both wool and linen fibers present, hence a shatnez problem. If such a garment has been purchased it should be checked to see if it is permissible to wear.

Purchasing a garment from a frum or heimesh retailer, or which carries the label of a frum manufacturer does not mean that it is shatnez free.

Labels or retailers often contract with independent foreign subcontractors to produce garments. Unfortunately they either give loose specifications regarding internal materials, or the subcontractor makes unauthorized, undetected substitutions, resulting in the presence of shatnez. There have been many instances where reliance on the shatnez-free guarantees from frum retailers or manufacturers regarding their merchandise has been sadly mistaken.

Do not rely on any rule of thumb which states that the majority of garments made in country X are known to be free of shatnez, or conversely that the majority of garments made in country Y are known to contain shatnez.

Clothing manufacture is constantly changing. Manufacturers are always looking for cheaper suppliers and therefore the internal components of garments themselves constantly change. With the exception of traditional bespoke tailored garments and some military clothing made in Eastern Europe, there is almost no national culture of clothing manufacture remaining in the world.

You may not try on a garment that is known to contain shatnez.

If a garment is not known to contain shatnez, (meaning it might or might not) it may be tried on for size, but not worn until checked. A garment made by a manufacturer known to always contain shatnez (such as Hugo Boss or Aquascutum) according to most poskim, may not even be tried on.

Joseph A. Bank suits may contain shatnez.

Joseph A. Bank suit are very popular because they provide good value - are well made and often on sale at good prices. Many of their suits, particularly the Signature Gold series, often contain shatnez in the collar. All Joseph A. Bank suits, as with all men’s suits should be checked for shatnez. All are considered safeik shatnez and may be tried on.

All vintage garments made before 1939 and any bespoke tailored garments should be checked for shatnez.

Before WWII there were no synthetic fibers in practical use in the garment industry. Linen was used extensively as interfacing in all kinds of garments. Bespoke London tailors continue to use linen today in wool suits as a matter of tradition. This clothing is beautifully made and looks like a better value than its modern counterparts, but beware...the cost to remove the shatnez and remake the garment may be prohibitive.

Suits may be returned if found to contain shatnez after checking but before any alterations are made.

SOURCES FOR SHATNEZ INFORMATION

Lakewood Shatnez Laboratory

Star-K

Shatnez Testers of America

RabbiKaganoff.com

Boston Shatnez Laboratory

A BRIEF PRIMER ON TEXTILE FIBERS

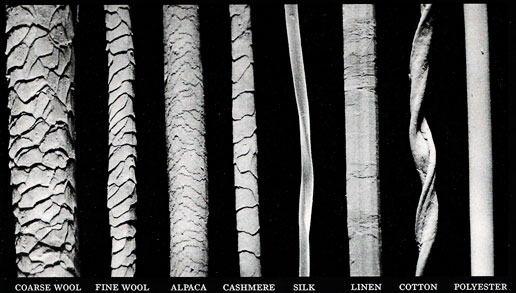

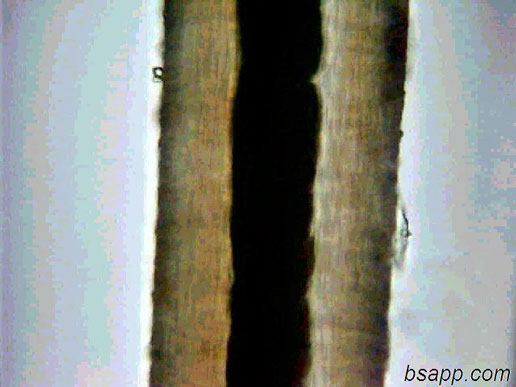

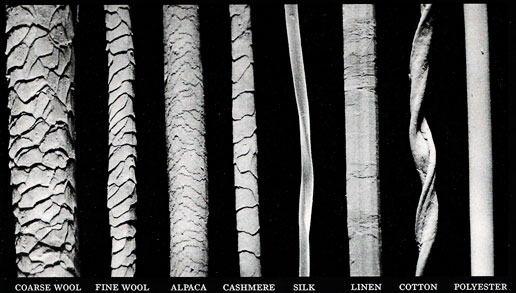

Animal fibers consist of an outer cuticle, an inner cortex, and a

central medulla. Wool is identified by its scaly cuticle, while

horse, camel, and rabbit have a pronounced and distinctly shaped

medulla. Plant fibers also have an exterior cuticle, a cortical region,

and a central lumen. Cotton is a collapsed tube; silk a fine

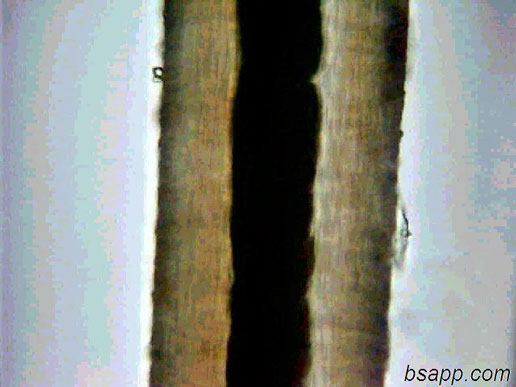

glass-like ribbon. Linen, like its relatives, show intermittent

node-like dislocations with patterns characteristic of its type.

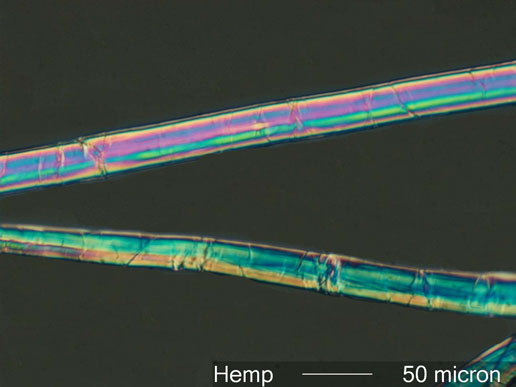

Silk is a natural extrusion from the silk worm. Synthetic fibers

such as nylon are also extrusions, resembling clear

round rods. Polyester and acrylic often appear to be speckled

with dye pigment. Rayon and acetate, unlike the true synthetics,

are artificial reconfigurations of cellulose. Most fibers consist

of at least some crystalline material thereby exhibiting some unique

angular characteristics under polarized light.

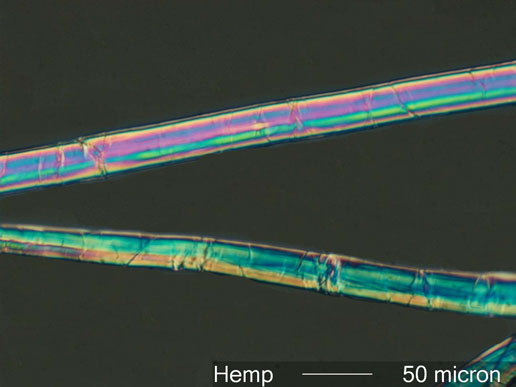

The gemara uses the word "canvas" to refer to the linen relative,

lookalike, and substitute, hemp. The cognate "canvas" appears in English

as the fabric we know as canvas, which is a distortion of the source

word, cannabis. While wool fabric is warm, soft, and takes dyes

well, linen has superior tensile strength, is sometimes difficult to

dye, but makes an excellent structural thread to hold a garment

together. In a man's or woman's suit the outer shell is likely to

be wool, the inner lining rayon or acetate, but the concealed

interfacing layers which shape and stiffen the garment may be a variety

of fabrics depending on design purpose. The principle interfacing

in the collar and chest is also called "canvas." The chest or front

canvas often contains cotton, wool, poly, and horsehair for

stiffness. The collar canvas may be linen, and in traditional

bespoke made-to-measure garments often is. Although synthetic

fibers are usually stronger and cheaper than their natural counterparts,

they lack one critical attribute...flexible memory. Natural

fibers can be folded or crimped, but will bounce back in the presence of

heat (ironing) to be re-set; synthetic fibers have a one-way memory and

once set are difficult or impossible to re-set.

Lakewood Shatnez Laboratory

Star-K

Shatnez Testers of America

RabbiKaganoff.com

Boston Shatnez Laboratory

A BRIEF PRIMER ON TEXTILE FIBERS

The above scanning electron microscope

composite of fibers typically found in clothing manufactured today

demonstrates why microscopic examination is the definitive test of

identity. Shatnez is the

combination of linen and sheep or lamb's wool. Alpaca, cashmere

(goat), angora (rabbit), camel hair, horse hair, and other animal fibers

are not a shatnez problem

unless mixed with sheep's wool. Similarly, jute, hemp (cannabis),

and ramie, which all come from the same family of plant fibers as flax

(linen), do not constitute a shatnez problem unless actually mixed with linen.

Shatnez

exists when as little as one thread of linen exists in a wool garment,

or vice versa. A thread, that which has been combed and spun from

fibers, is the threshold unit beyond which bitul (nullification) is impossible. Below that threshold and before spinning into thread it is possible to m'vatel

(nullify) the presence of linen or wool fibers with a majority of some

other fiber. As examples: a preponderance of hemp fibers could

nullify the presence of linen fibers, likewise, camel hair could nullify

the presence of sheep's wool. If threads or fibers constituting shatnez are apparent in the garment, either to the naked eye or through a microscope, they are considered to be nikkar (visible) and can be sold or given to a goy. If it's known that single thread of linen exists in a wool garment but it can't be found by any means (not nikkar),

it cannot even be sold to a goy. However, since the prohibition

is only for wearing or draping it upon your person, it still remains suitable for

framing.

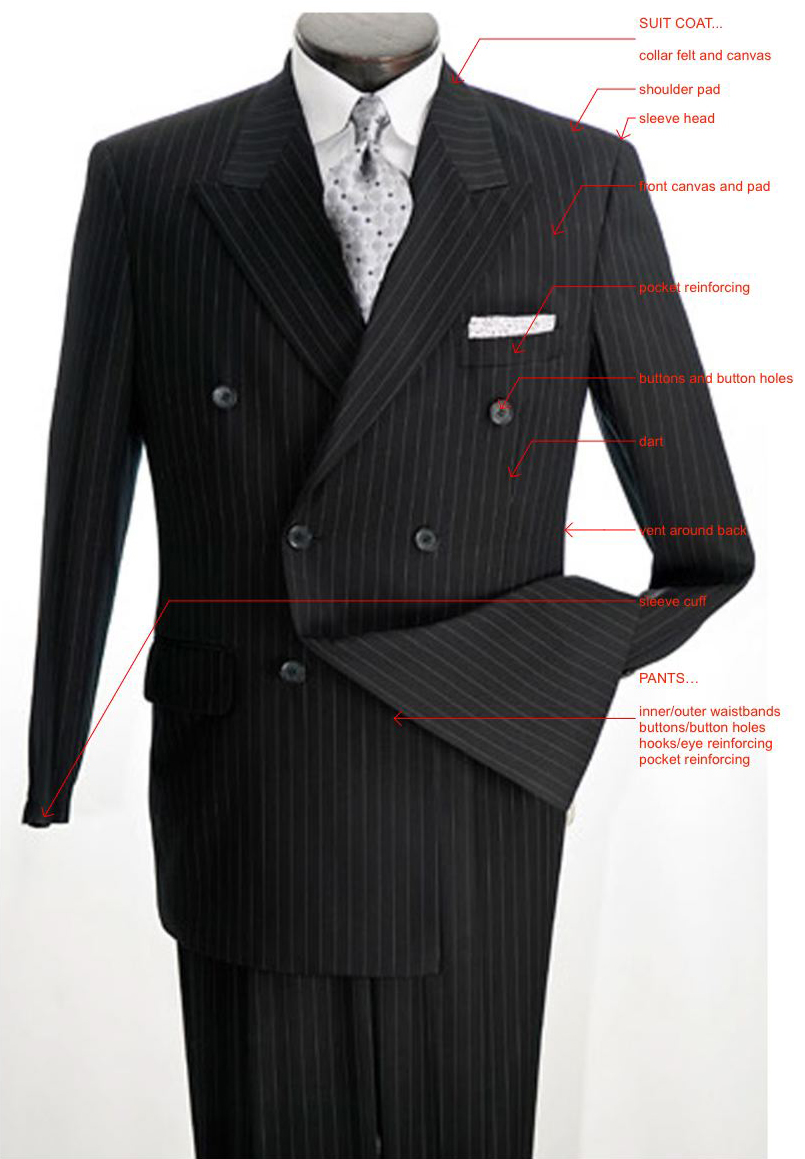

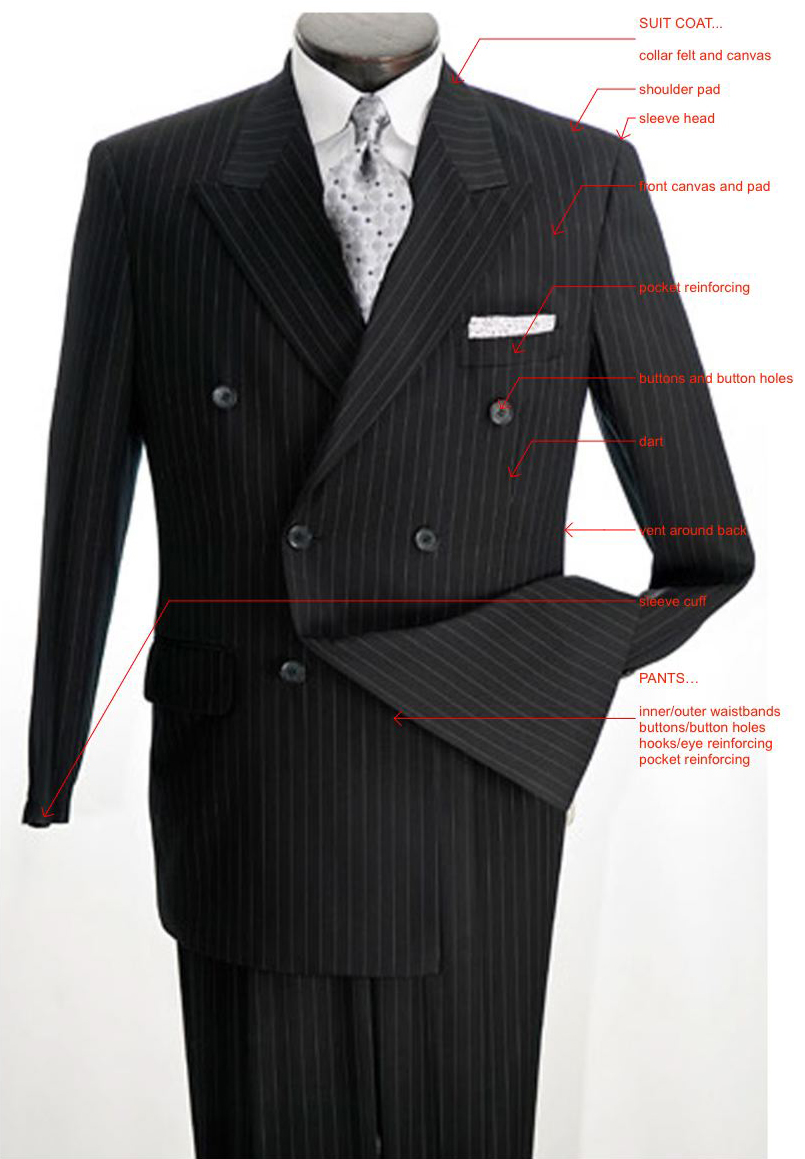

ANATOMY OF A SUIT

This is not intended as a shatnez

tester's instruction manual, and we strongly advise you not to try this

at home. But, we would like to give you a glimpse of some of the

places where linen is likely to lurk in a typical wool suit. In

the example above the shell fabric will likely be wool as labelled, but

the pin stripe could be anything from wool, silk, synthetic, or

linen. The chances of finding a greater variety of fiber types is

multiplied in a plaid jacket.

JACKET...

collar canvas: Beneath the wool felt on the back of the collar (and sometimes embedded within it), there will usually be a layer of fairly stiff interfacing of horsehair canvas, synthetic, cotton, or traditionally, linen. Additionally, a reinforcing "fold tape" is usually sewn along the collar fold, which can sometimes be linen. If linen, it is fairly easy for the shatnez checker to completely remove the felt, canvas and tape, and it is one of the services we provide. We furnish new felt and interfacing which a local tailor can cut and attach, using the old felt as a template.

shoulder pad: This consists of a top and bottom cover, some interior batting or filler, and sometimes some additional layers of interfacing material. Linen can be found in any of those places, but most likely in the filler if it's reprocessed fiber.

sleeve head: Several layers of canvas, padding, and sometimes sponge pad are sewn into the armhole seam to give shape to the edge profile of the suit. Additionally, a reinforcing tape surrounds the armhole which can sometimes be linen.

front canvas and pad: Typically, the canvas itself is a combination of wool, cotton, polyester and stiffened with horsehair. However, there are many varieties, some of which contain linen. The pad is usually virgin material, natural or synthetic. In most manufactured suits, however expensive, the canvas structure extends about halfway down the coat, then continues as synthetic material fused to the shell fabric. The use of fusible material, adhesive backed and set with a hot press, is becoming more prevalent, even in more expensive garments. Although less frequent than in the past, successive dry cleanings may break the fused bond and cause bubbling in the jacket. In bespoke or made-to-measure suits, the canvas is fully floating, not fused, and extends to the bottom of the coat.

pocket reinforcing: This is most often some kind of paper or synthetic "Pellon," but in some custom suits this can be, especially in the breast pockets, extra layers of canvas or linen.

dart: The reinforcing of this shaping seam is usually Pellon, but in better suits linen.

vent: Reinforcing similar to "dart" above.

sleeve cuff: Reinforcing similar to "dart" above.

buttons and button holes: Linen is traditionally used as a structural thread for hard-wearing items like buttons and button hole reinforcing. Linen, however, tends to jam the buttonhole sewing machine, so is rarely used on most manufactured suits. Buttons sewn with linen thread therefore have to be done by hand. Buttonholes were traditionally reinforced with a linen thread sewn into the surging around the button hole, and called a "gimp." They are rarely found today.

PANTS...

inner and outer waistbands: While the internal stiffening in most trouser waistbands is a stiff synthetic mesh, it could be linen. The outer waistband like pocket material and jacket lining is usually an acetate or rayon material.

buttons, buttonholes: see above

belt loops: Usually Pellon or some other synthetic material, and rarely linen.

hooks and eyes: see "inner waistband" above

JACKET...

collar canvas: Beneath the wool felt on the back of the collar (and sometimes embedded within it), there will usually be a layer of fairly stiff interfacing of horsehair canvas, synthetic, cotton, or traditionally, linen. Additionally, a reinforcing "fold tape" is usually sewn along the collar fold, which can sometimes be linen. If linen, it is fairly easy for the shatnez checker to completely remove the felt, canvas and tape, and it is one of the services we provide. We furnish new felt and interfacing which a local tailor can cut and attach, using the old felt as a template.

shoulder pad: This consists of a top and bottom cover, some interior batting or filler, and sometimes some additional layers of interfacing material. Linen can be found in any of those places, but most likely in the filler if it's reprocessed fiber.

sleeve head: Several layers of canvas, padding, and sometimes sponge pad are sewn into the armhole seam to give shape to the edge profile of the suit. Additionally, a reinforcing tape surrounds the armhole which can sometimes be linen.

front canvas and pad: Typically, the canvas itself is a combination of wool, cotton, polyester and stiffened with horsehair. However, there are many varieties, some of which contain linen. The pad is usually virgin material, natural or synthetic. In most manufactured suits, however expensive, the canvas structure extends about halfway down the coat, then continues as synthetic material fused to the shell fabric. The use of fusible material, adhesive backed and set with a hot press, is becoming more prevalent, even in more expensive garments. Although less frequent than in the past, successive dry cleanings may break the fused bond and cause bubbling in the jacket. In bespoke or made-to-measure suits, the canvas is fully floating, not fused, and extends to the bottom of the coat.

pocket reinforcing: This is most often some kind of paper or synthetic "Pellon," but in some custom suits this can be, especially in the breast pockets, extra layers of canvas or linen.

dart: The reinforcing of this shaping seam is usually Pellon, but in better suits linen.

vent: Reinforcing similar to "dart" above.

sleeve cuff: Reinforcing similar to "dart" above.

buttons and button holes: Linen is traditionally used as a structural thread for hard-wearing items like buttons and button hole reinforcing. Linen, however, tends to jam the buttonhole sewing machine, so is rarely used on most manufactured suits. Buttons sewn with linen thread therefore have to be done by hand. Buttonholes were traditionally reinforced with a linen thread sewn into the surging around the button hole, and called a "gimp." They are rarely found today.

PANTS...

inner and outer waistbands: While the internal stiffening in most trouser waistbands is a stiff synthetic mesh, it could be linen. The outer waistband like pocket material and jacket lining is usually an acetate or rayon material.

buttons, buttonholes: see above

belt loops: Usually Pellon or some other synthetic material, and rarely linen.

hooks and eyes: see "inner waistband" above